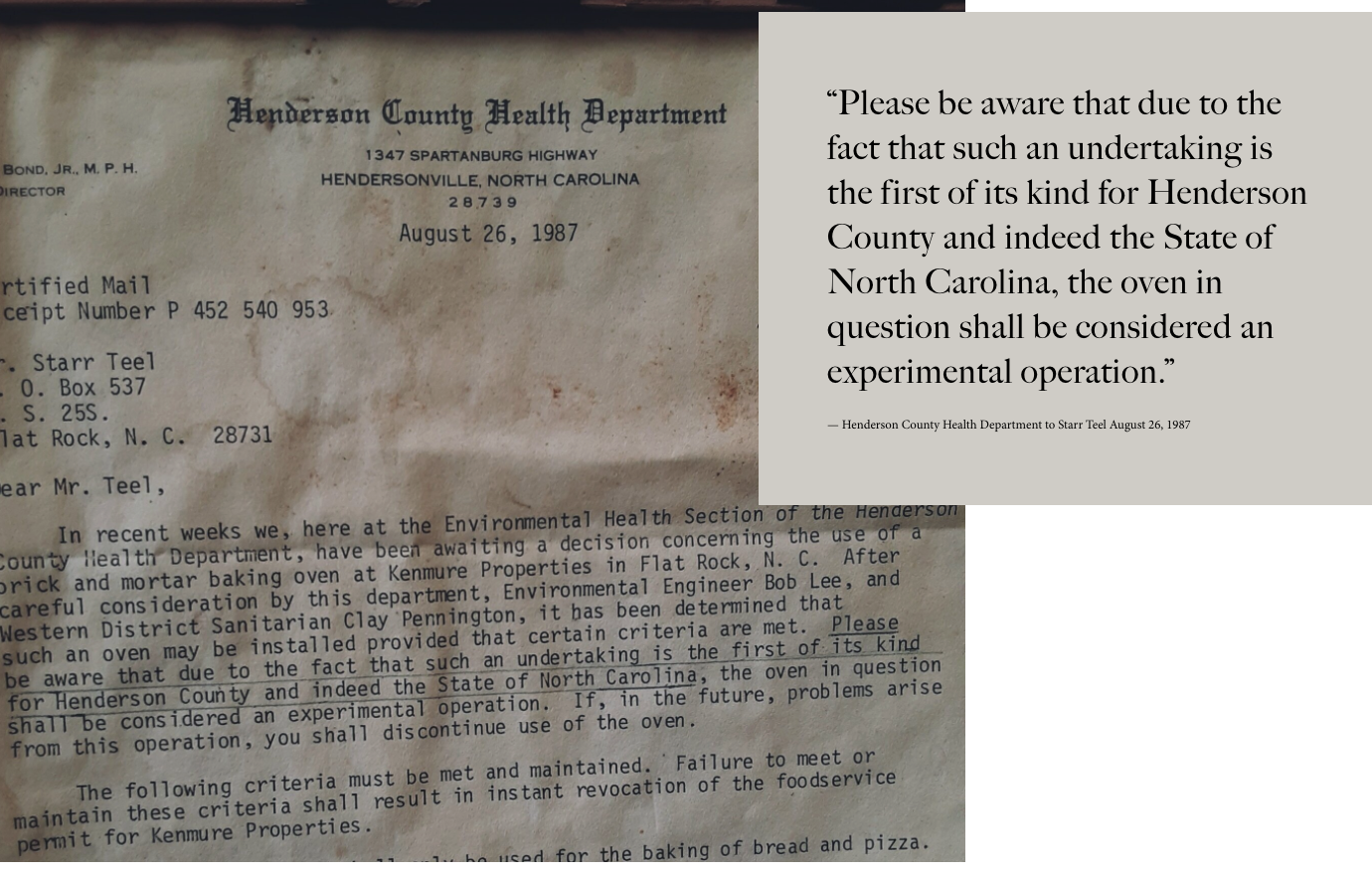

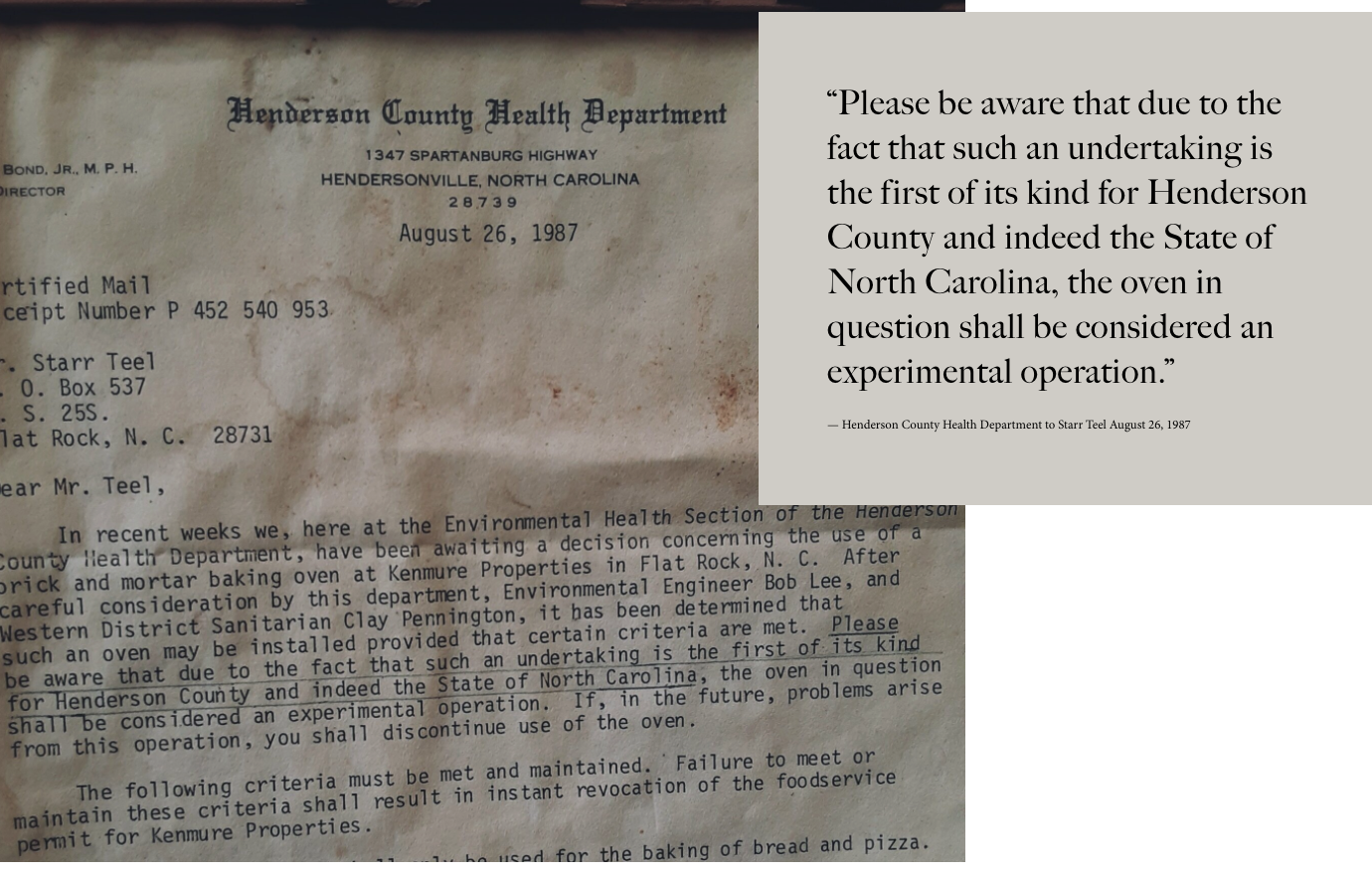

Henderson County Health Department Letter to Starr, 1987

Please be aware that due to the fact that such an undertaking is the first of its kind in Henderson County and indeed the State of North Carolina, the oven in question shall be considered an experimental operation.

Bricks for Arch

Jet High Duty 3” Bricks make up the arch of the traditional Beehive oven. Our arch is built higher than a traditional pizza oven, making the heat from the fire refract at lower temperatures that sustain our “low & slow“ philosophy for meats. These bricks, as well as the Super High Duty ones that make up the hearth, and the Medium Duty that form our walls, expand and contract in response to temperature changes. This makes particular and thorough insulation a key element to building any oven, particularly this one.

Masonry Work

Rick & Drew Metcalf, our overall master craftsmen father-son duo, laying Super Duty 3” Brick on the hearth and medium-duty brick walls, bound not by masonry cement, but gray refractory high temp mortar which gets stronger under high temperatures.

Rick Metcalf installing ceramic blanket.

Drew Metcalf finishes welding connections of smoker framework.

Starr and Jack Nash

If you ask Starr Teel how he accomplishes what he does, he will inevitably answer, “by surrounding myself with smart, caring, passionate people and asking questions.”

Nash insulated oven doors.

10” triple wall stainless steel flue.

Oven in Operation

The hybrid nature of the Campfire oven makes it unusual, having the flu at the rear rather than the front and building the arch higher than standard not only provides space for racks to smoke fish and meats, but also facilitates bigger fires, the long-burning coals of which are then repurposed to fuel our Santa Maria wood-fire grill.

Starr with the Campfire Grill wood-fired oven.